The Challenge

NASA University Leadership Initiative (ULI)

This NASA ULI called to disrupt the aviation industry with a bold goal: achieve Zero Emission Aviation by 2050. The hydrogen carrier ammonia is proposed for a Zero-Carbon Engine Core with Supercritical Carbon Dioxide Power Cycle for Onboard Power as an innovative concept and technology to pave the way for a future where aircraft leave no environmental footprint. This teams took on the challenge to collaborate with industry and tackle this multi-disciplinary, multi-institutional challenge, with a focus on practical, transformational solutions for a zero-emissions future.

Our Idea

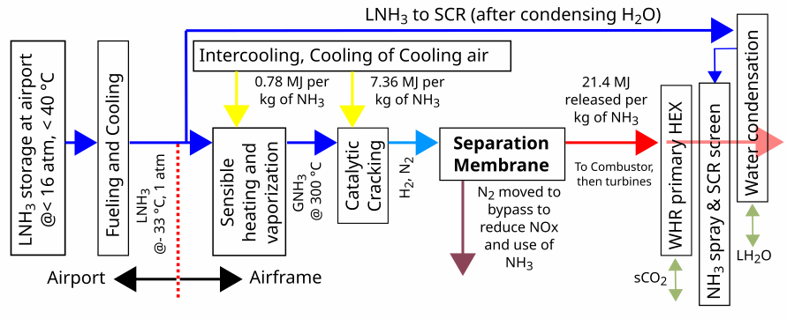

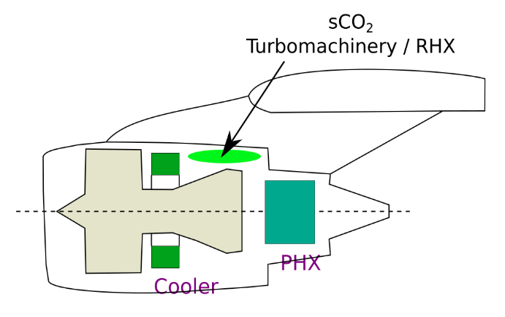

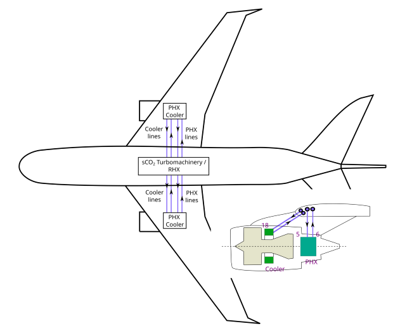

The team behind the project aims to revolutionize the aviation industry with a focus on zero-emissions by 2050. The main idea is to introduce liquid ammonia as a hydrogen carrier and a supercritical carbon dioxide (sCO2) waste heat recovery system as the key innovations. The target application is a commercial flight with a range of 3550 nm and a capacity of 200 passengers. Liquid ammonia stored onboard at -33C will eliminate the need for refrigeration or cryo-cooling of other hydrogen-based solutions and improve engine efficiency through thermal management such as intercooling and cooled cooling air. Additionally, the use of ammonia in combustion results in the near to complete elimination of NOx from the exhaust stream, and the closed-loop sCO2 power system produces electricity from engine heat and reduces contrail formation. The project addresses three technical challenges: elimination of emissions, airframe integration, and safety, logistics and cost considerations. The team will conduct multidisciplinary optimization to balance trade-offs, minimize weight increase, and optimize energy usage. The introduction of ammonia as a fuel will require significant logistical changes and cost management to comply with environmental and safety regulations.

Our Goal

- To Minimize NOx, NH3, and H2O concentration in the engine exhaust under cruise conditions.

- To Minimize adverse impact on engine/airplane operation when new components are integrated into the engine and airframe, including MTOW, Realized lower heating value, Start-up time

- To Minimize the cost of upgrade and operation when new technologies are introduced to airports and airplanes, including total fuel cost, airframe cost increase, gate cost increase, dollar per passenger mile increase

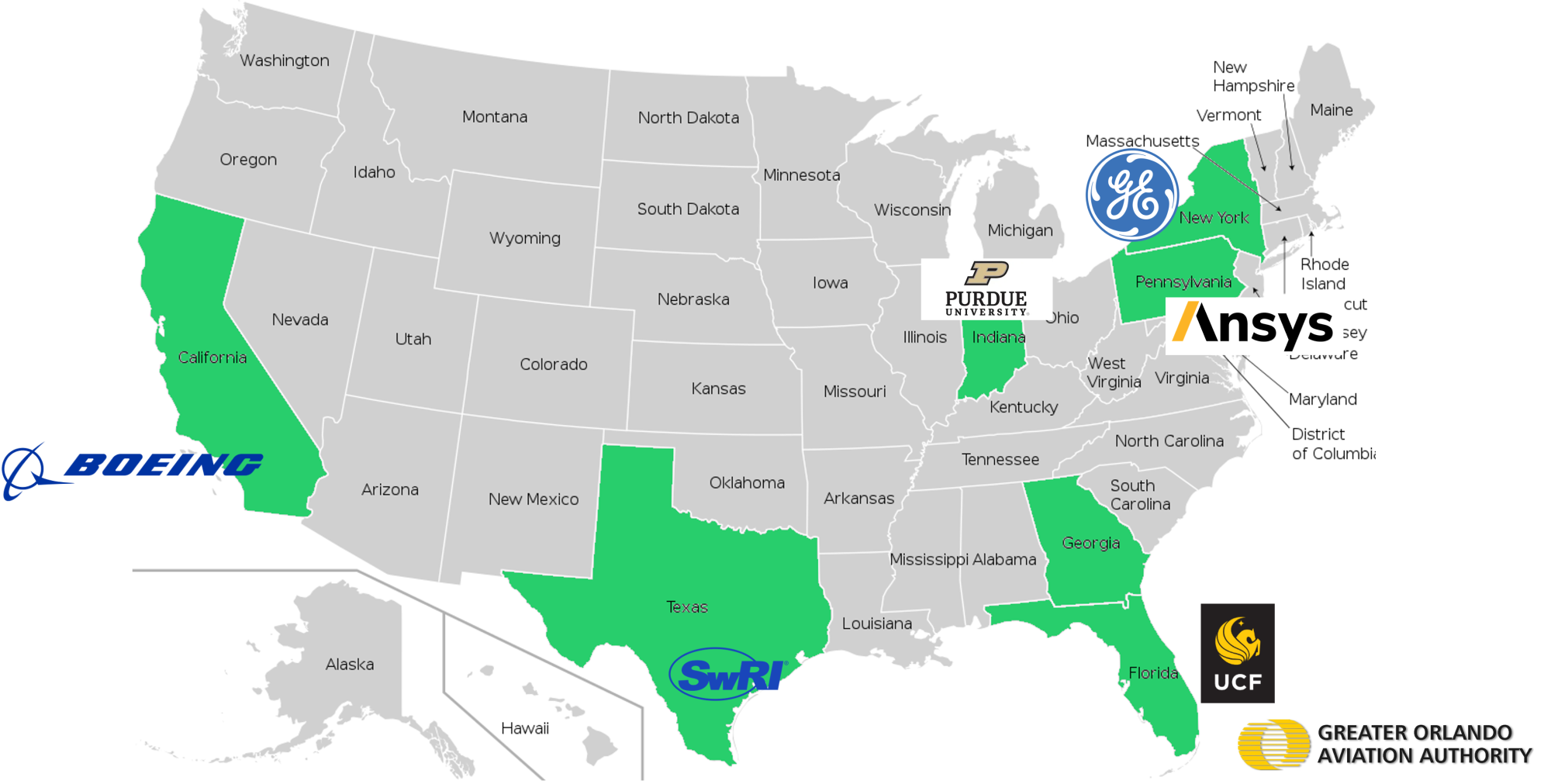

The Team

Principal Investigator: Dr. Jay Kapat

Pegasus Professor and Trustee Chair

Mechanical & Aerospace Engineering

Center for Advanced Turbomachinery and Energy Research

University of Central Florida

Project Manager: Dr. Marcel Otto

P3 PostDoctoral Research Associate

Center for Advanced Turbomachinery and Energy Research

University of Central Florida