Recently expanded in 2008 with the addition of a new building, the Siemens Energy Center (SEC) has over 10,000 sq ft of space for experimental rigs, staff/student offices, Siemens meeting room, and access to high performance computing clusters. The lab is fully equipped with various measurement equipment; such as scientific cameras, hotwire probes (single and multi-wire), pitot and multi-hole probes, manometers, microphone and accelerometer arrays, high speed data acquisition systems, pressure scanning systems, automated traverse systems, Particle Image Velocimetry, Laser Induced Florescence, Laser Doppler Velocimetry, Schlieren system, high speed cameras, temperature and pressure sensitive paints, transient and steady thermochromic liquid crystals, and various qualitative flow visualization systems, along with the respective calibration equipment for each. Additionally, the facility is equipped with several multi-processor workstations, high performance computers, and access to UCF’s STOKES (http://webstokes.ist.ucf.edu/) HPCC for computational efforts. Software access includes several CAD/CAM packages, LabVIEW, MATLAB, GasTurb, NPSS, MathCAD, ANSYS, Fluent, Star CCM+, GridPro, and OpenFOAM, among others. Researchers have access to a well equipped workshop, including a large scale CNC. The facility is staffed with several undergraduate, graduate, and post-graduate research associates, as well as technicians. The facility provides a secure location for open and proprietary equipment and data; including a closed circuit surveillance system and data encryption.

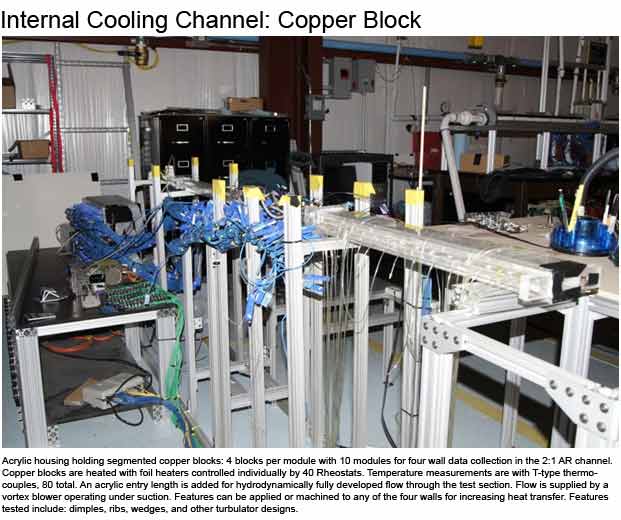

The laboratory has multiple wind tunnels and flow facilities: transonic closed-loop cascade with relatively high density-ratio, multi-plenum film cooling capability; tunnel for basic film cooling study with coupons; an annular sector coupon based film cooling tunnel with rotating wakes; tunnel for study of coupled film (or effusion or transpiration)/impingement cooling under realistic aerodynamic pressure variation at the film exit; tunnels for the studying of diffuser and ejector aerodynamics; a full scale gas turbine midframe sector; several sub-sonic flow ducts for detailed study of internal cooling characteristics with ribbed, turbulated, pin-finned structures with or without impingement; subsonic tunnel for airfoil aerodynamic characterization; blow-down type supersonic tunnel with up to Ma = 3.5 capability; a water tunnel for high Reynolds Number experiments; a blast tube; solar thermal collectors with phase changing thermal storage; environmental chambers; and a small scale turbojet for education and bio-fuel testing.